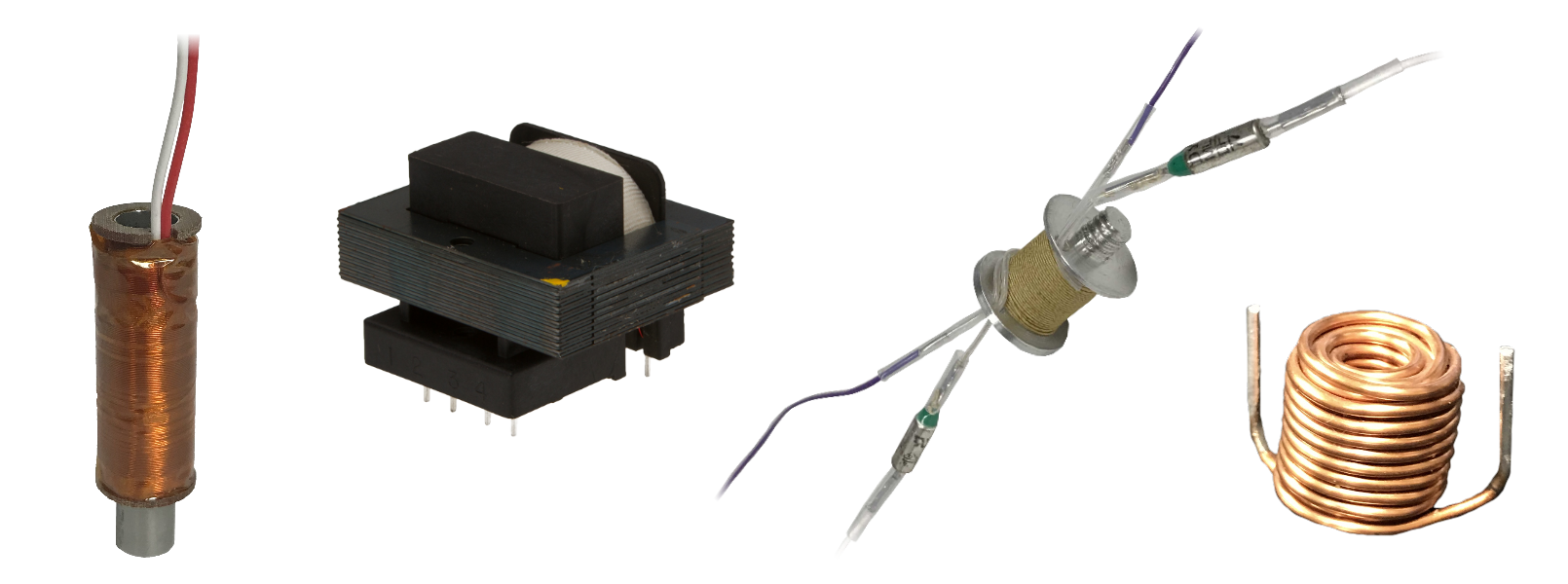

It can twist a meter of trifilar wire very well in just a fraction of a second. Then give it the shortest possible burst of power. The other end I tie in a knot and clamp it in the drill. Here I tie one end of the wires to something solid in the lab. But my favourite method involves a miniature 12V "dremel"-type drill. When I do it by hand I typically tie one end of the three pieces of wire round one screwdriver, and the other end around another screwdriver, then keep twisting them around relative to each other. Twisting the three pieces of wire in a trifilar can be a bit tedious. This is actually much easier to see in practice, than describe in words The trifilar wound transformer follows the same general idea but now you are connecting back both secondary wires. The output of the transformer is the bottom end of the secondary. In the diagrams, the top end of the transformer in the diagram, is one end of the windings. When it came to the trifilar transformer, only measuring continuity with the DVM helps to identify which winding is which. I happened to have green wire and orange wire, which makes the bifilar transformer easy. It helps if you have different coloured enamel on the wires. The tricky part is keeping track of which wire is which. You then wind this twisted wire 10 times through the core, to create a turn bifilar transformer. You want perhaps something like twists per inch twists per centimetrealthough it is not very critical. A "bifilar transformer" is made by taking two equal lengths of wire and twisting them together tightly. There is an even more dramatic increase in power if the PA bias voltage R5 adjustment is increased further. The bifilar transformer output significantly boosts the output power of the U3S, from typically mW to typically around mW.

0 kommentar(er)

0 kommentar(er)